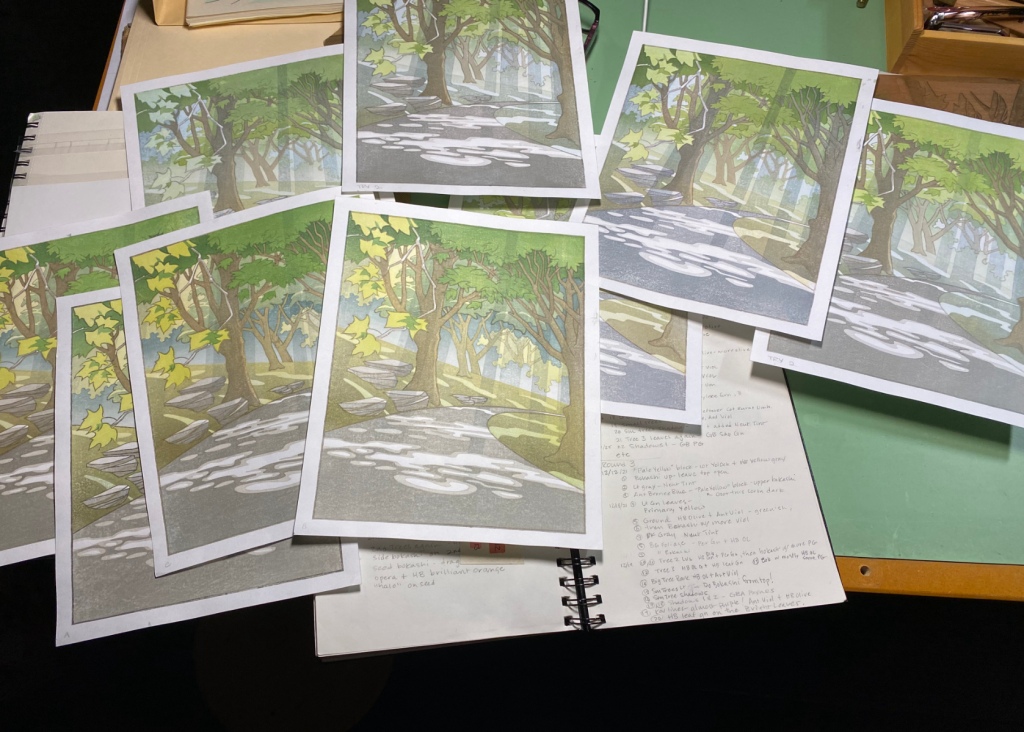

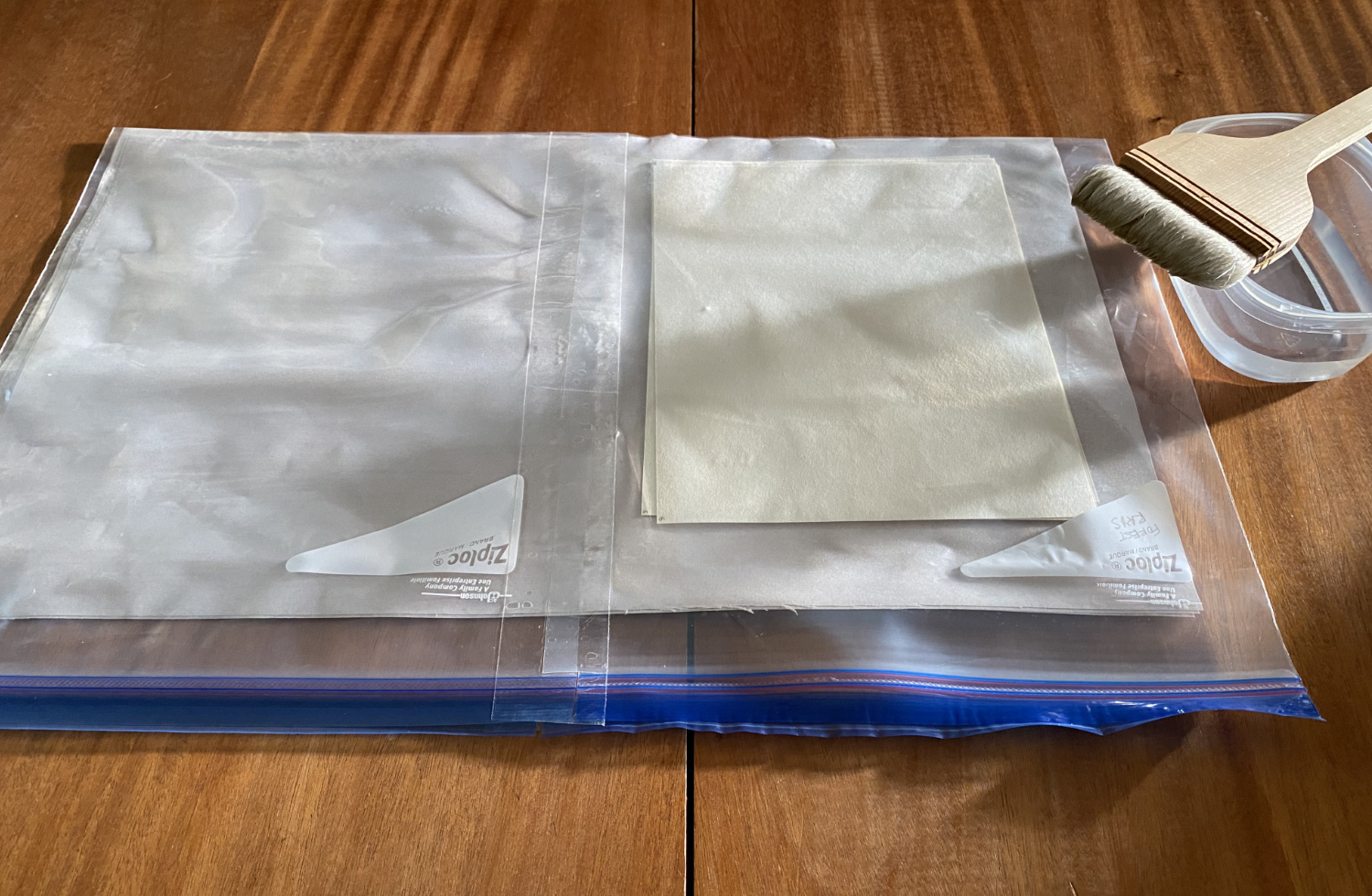

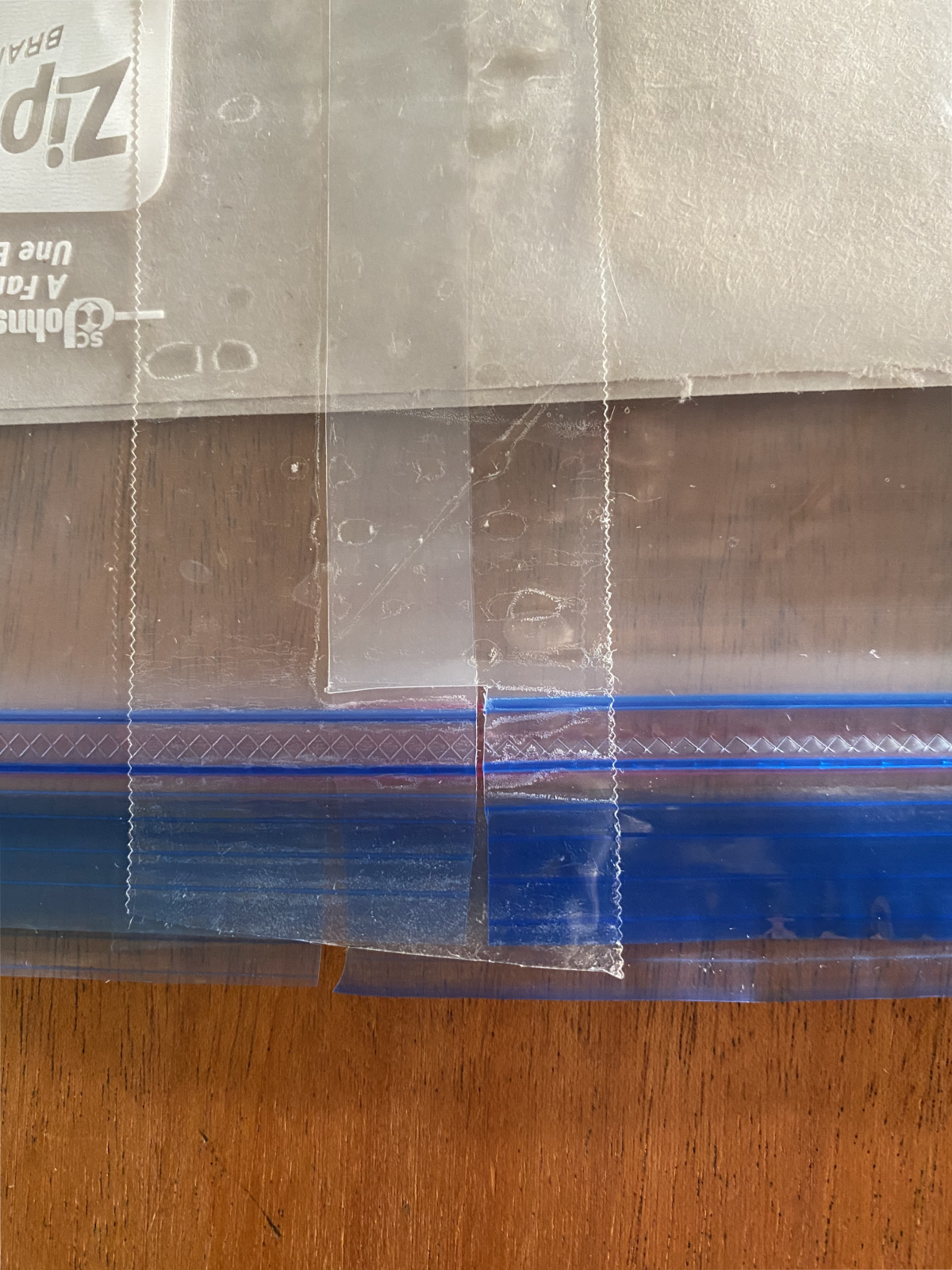

I’ve had a really productive day doing print-related things! I moistened the paper that I will use for Forest Rays.

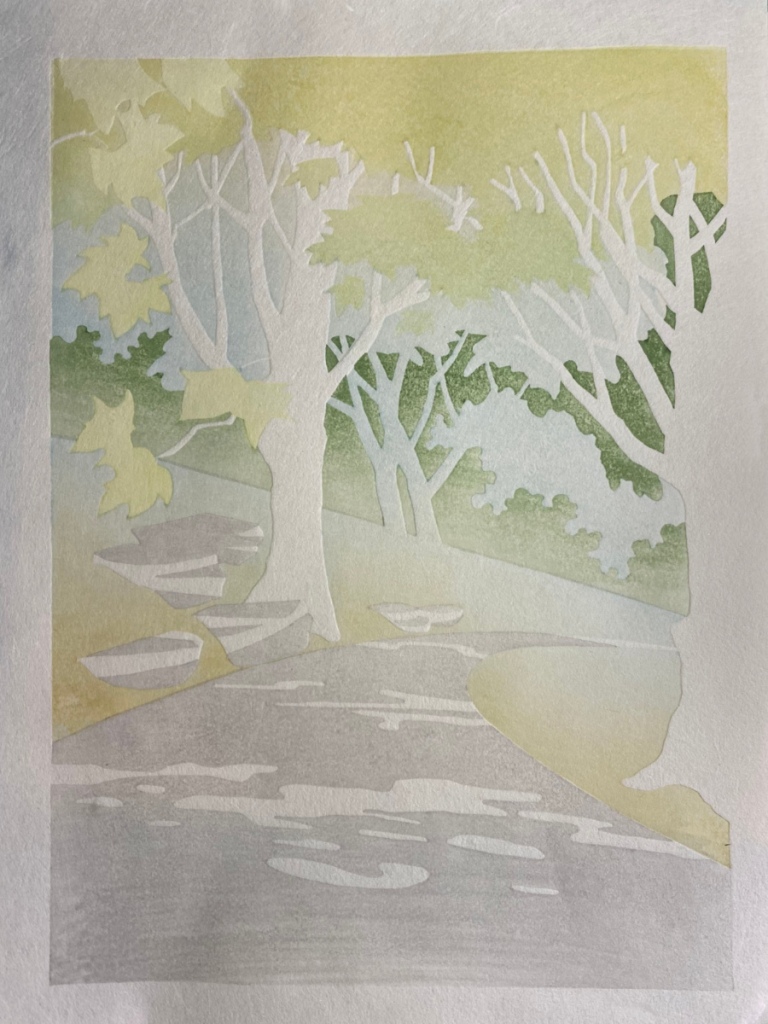

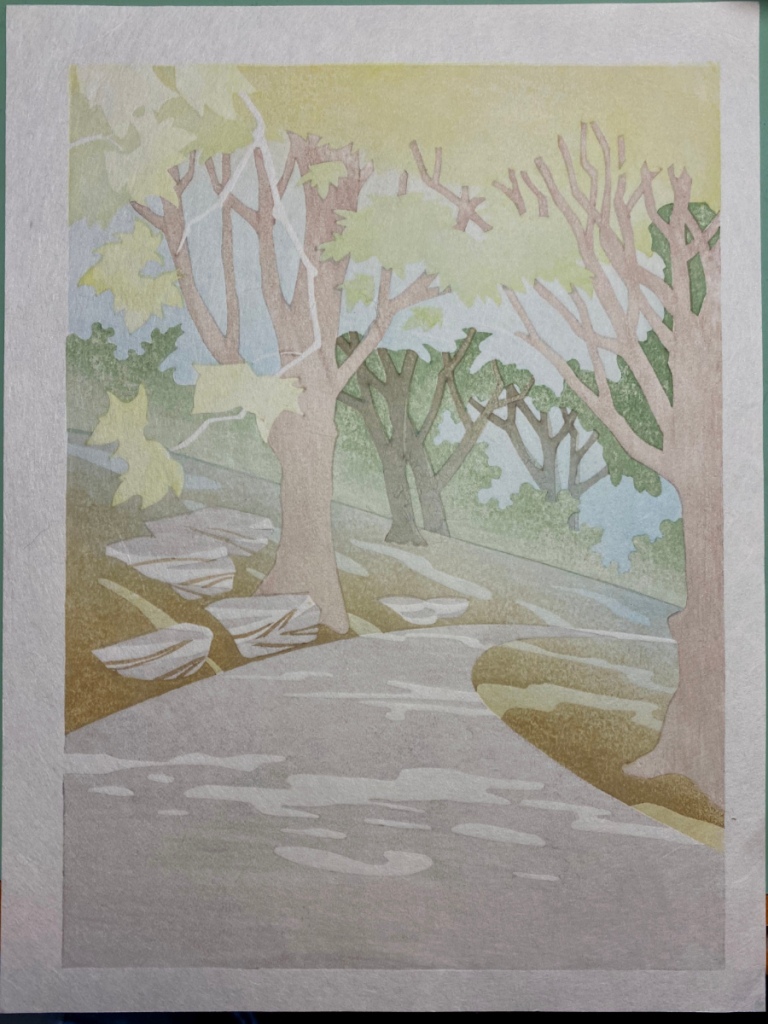

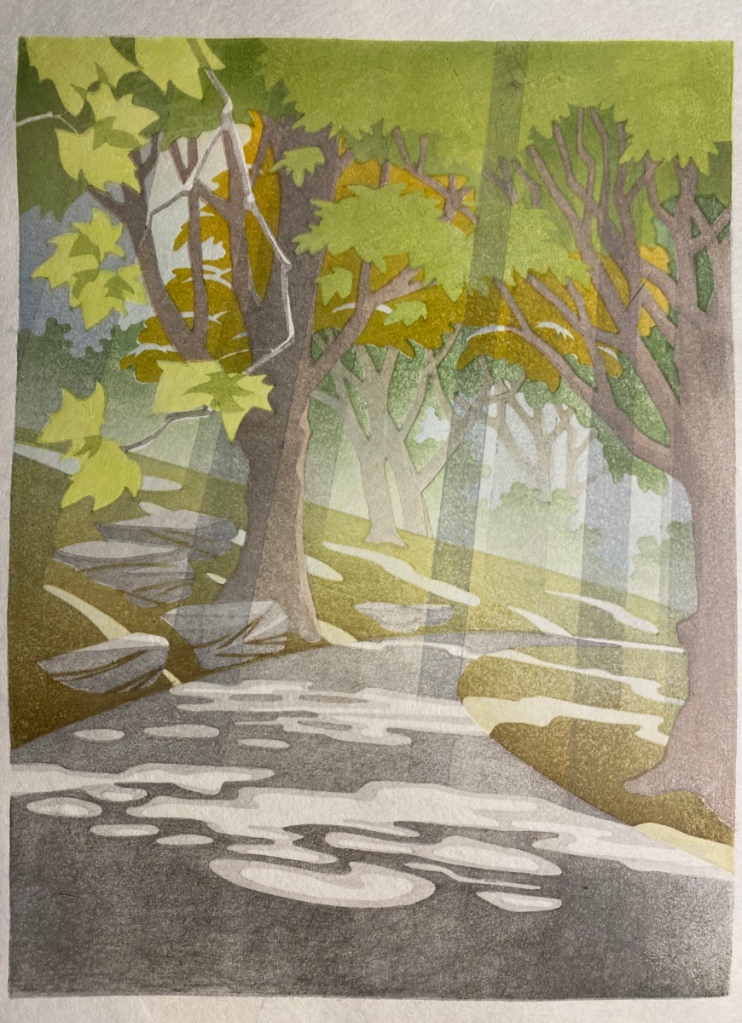

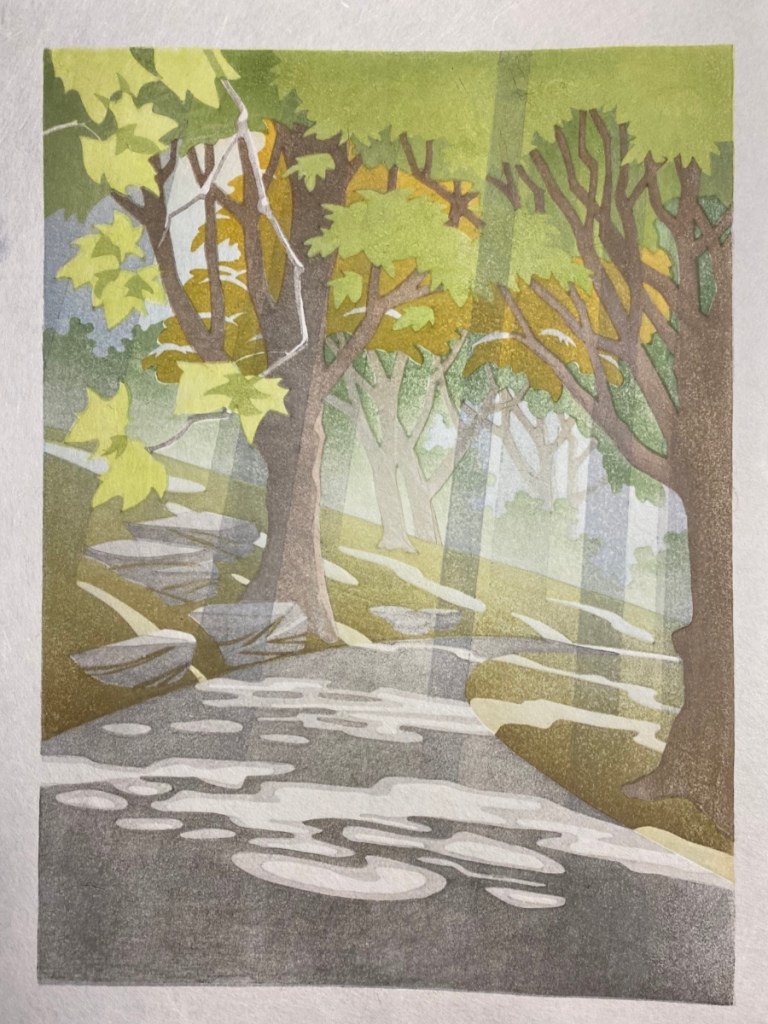

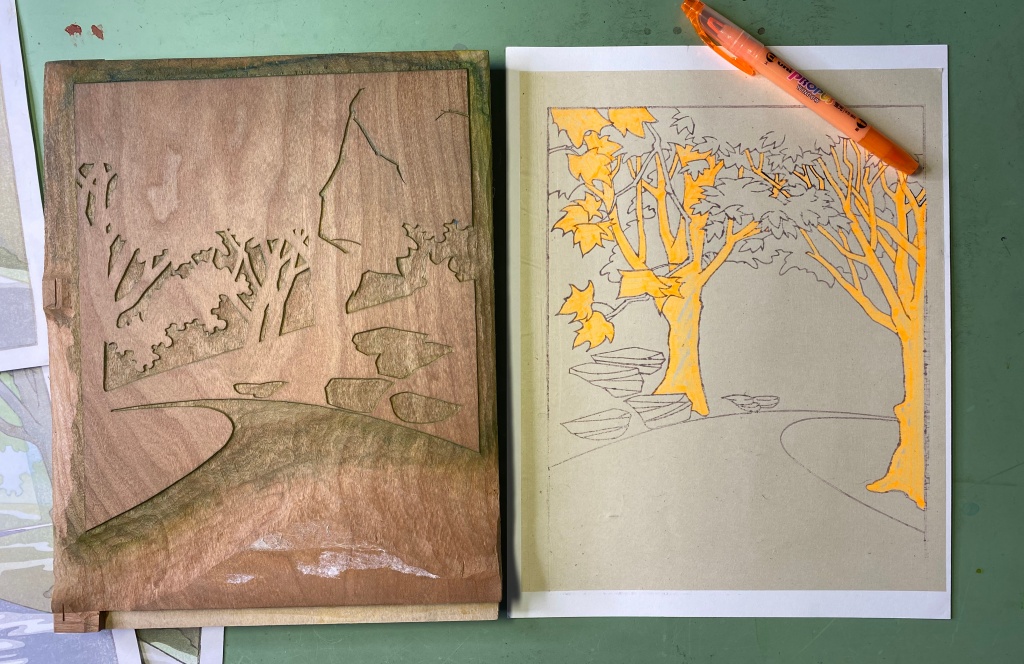

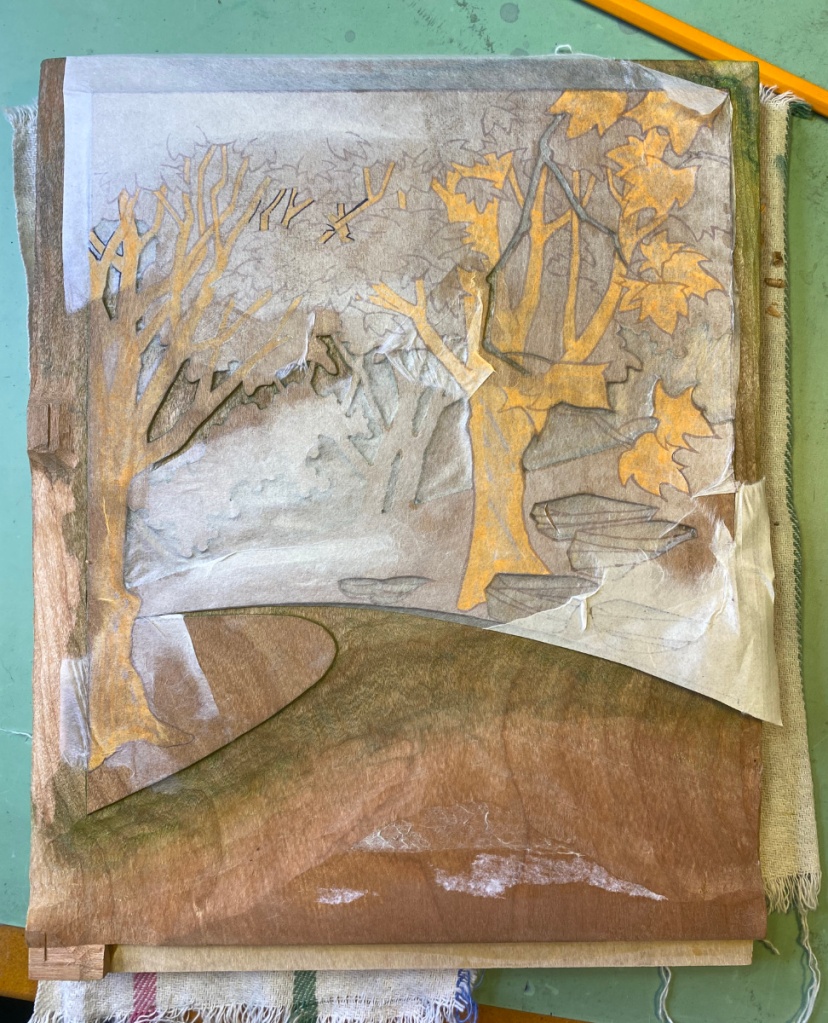

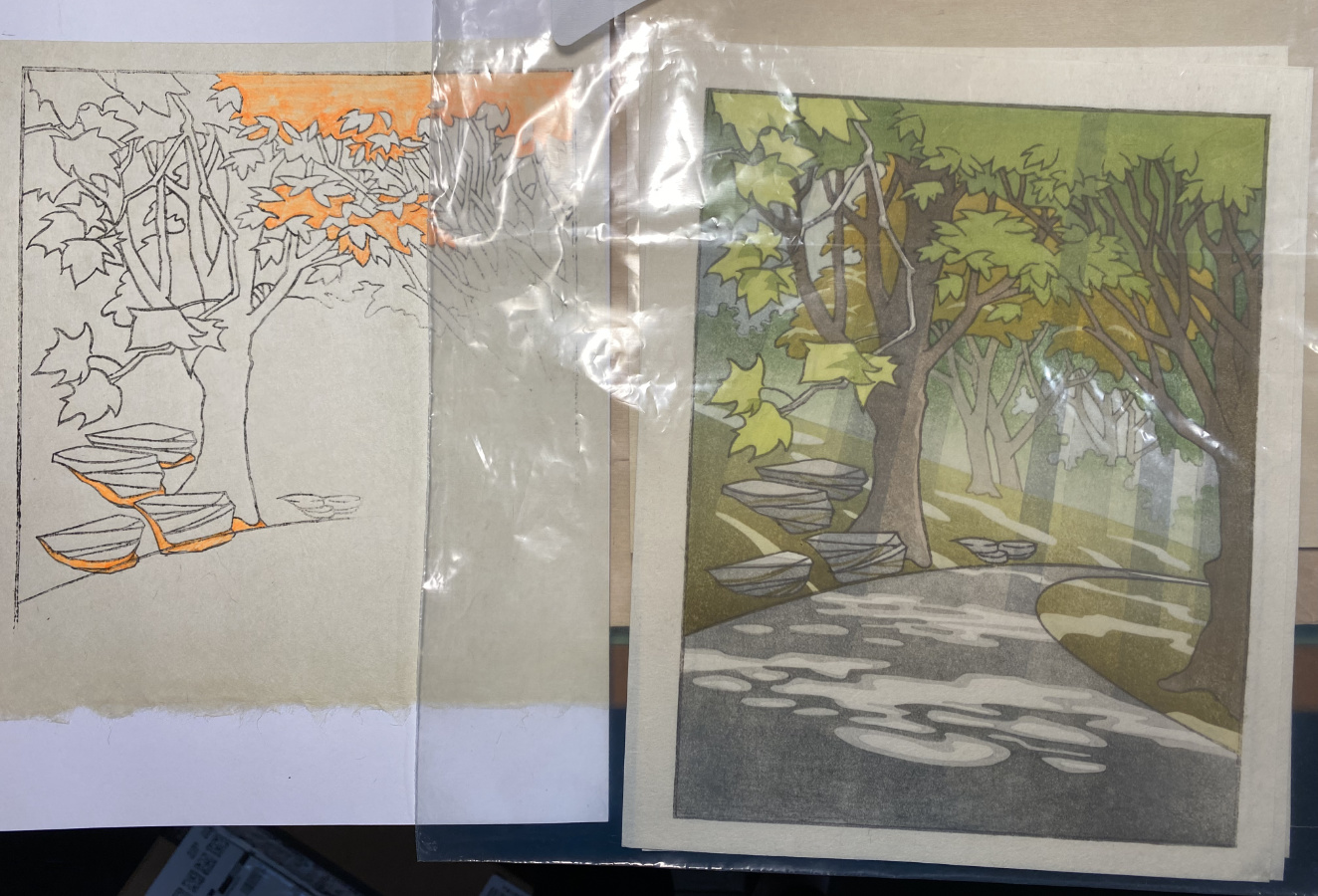

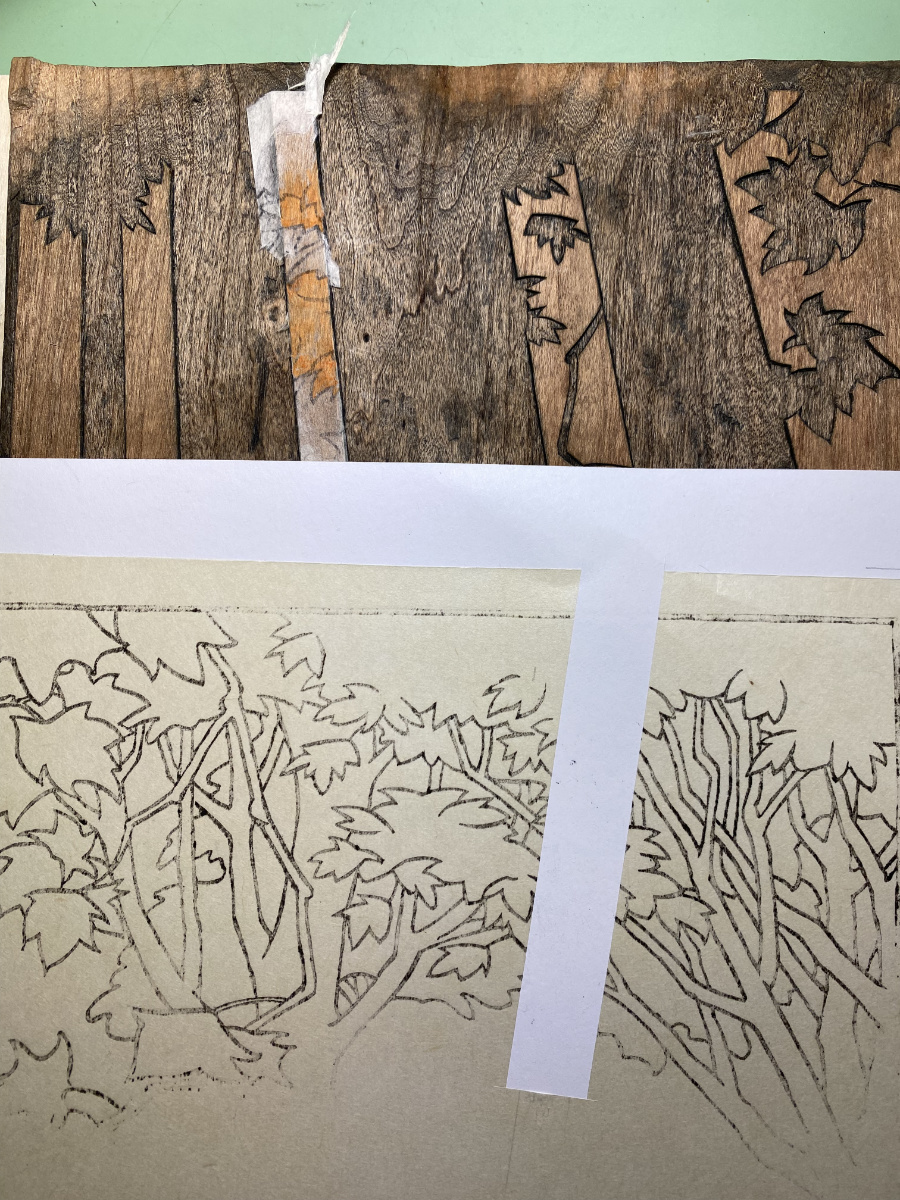

I decided to remove part of one of the columns of shadow, since it didn’t really look right overlapping the foliage at the top. I also decided to carve the other side of the shina ply I used for the newest block, to add deepness to that upper foliage while preserving some highlights. So, I made two new transfer sheets.

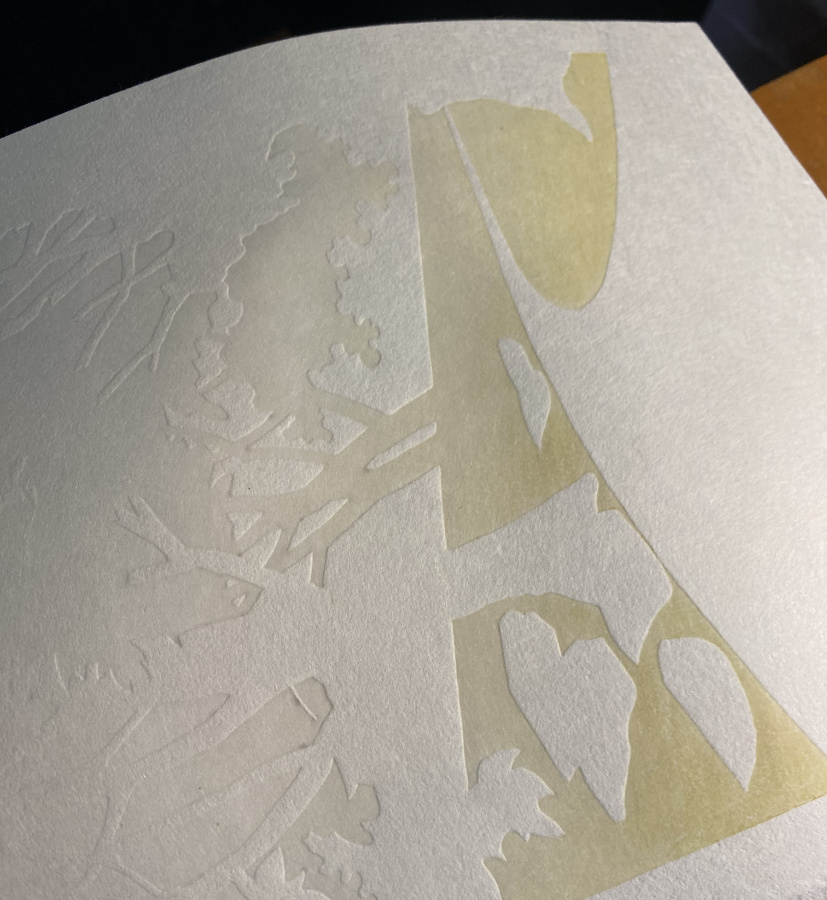

In the middle above is the current state of my test print inside a plastic bag, with the key lines added. The part of the shadow column I want to remove is about 1/3 of the way from the right edge – the part that crosses the lighter green at the top. Before pasting down the transfer to the shadow block (above right), I lightly cut the gampi with a knife so it would pull away from the backing sheet, then put glue only on that area, and pasted it down. You can see the place it formerly occupied in the transfer sheet remnants on the lower right. On far left is the second transfer sheet marked up for shading the foliage, and (why not, while I am at it!) shadows for the rocks.

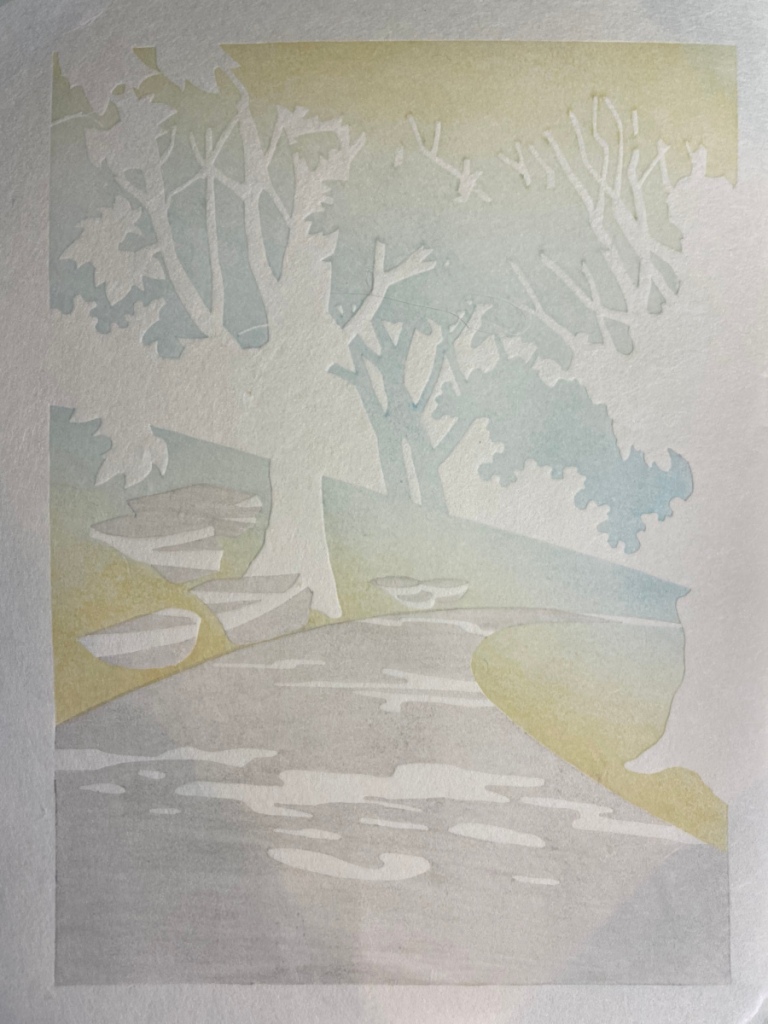

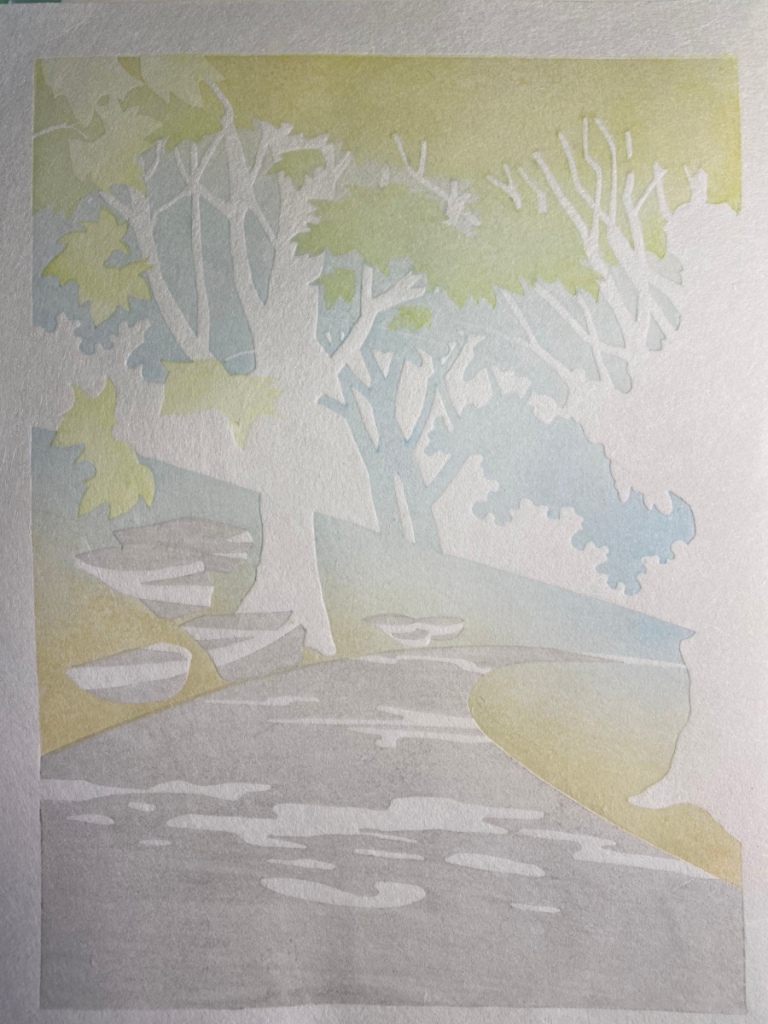

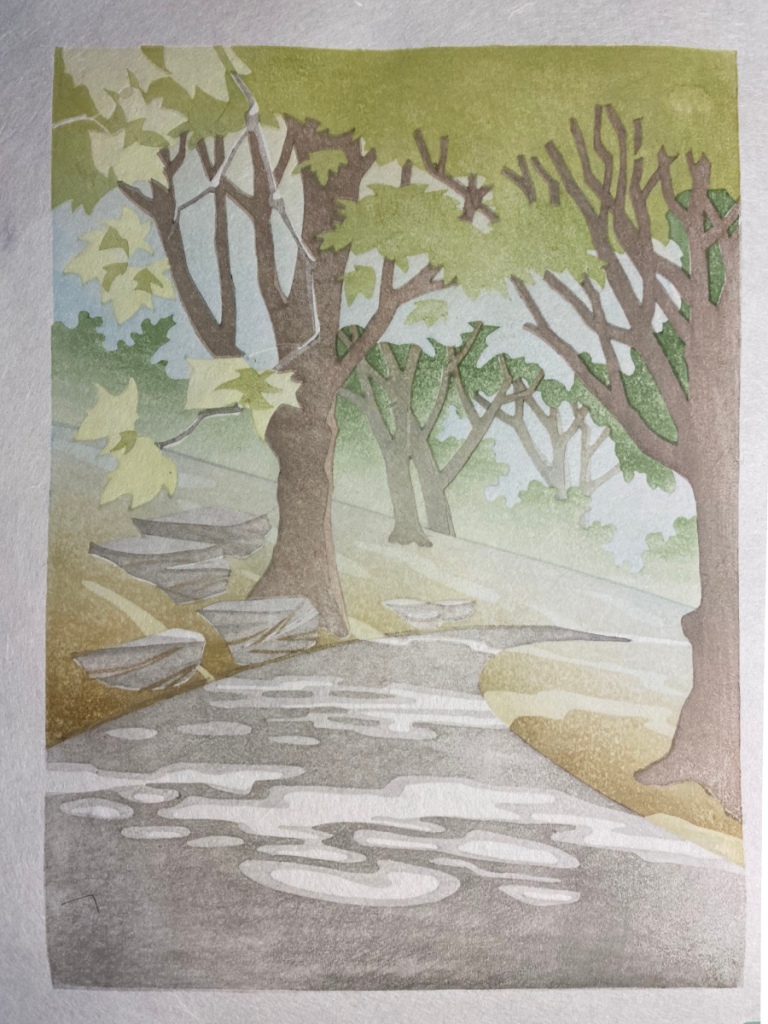

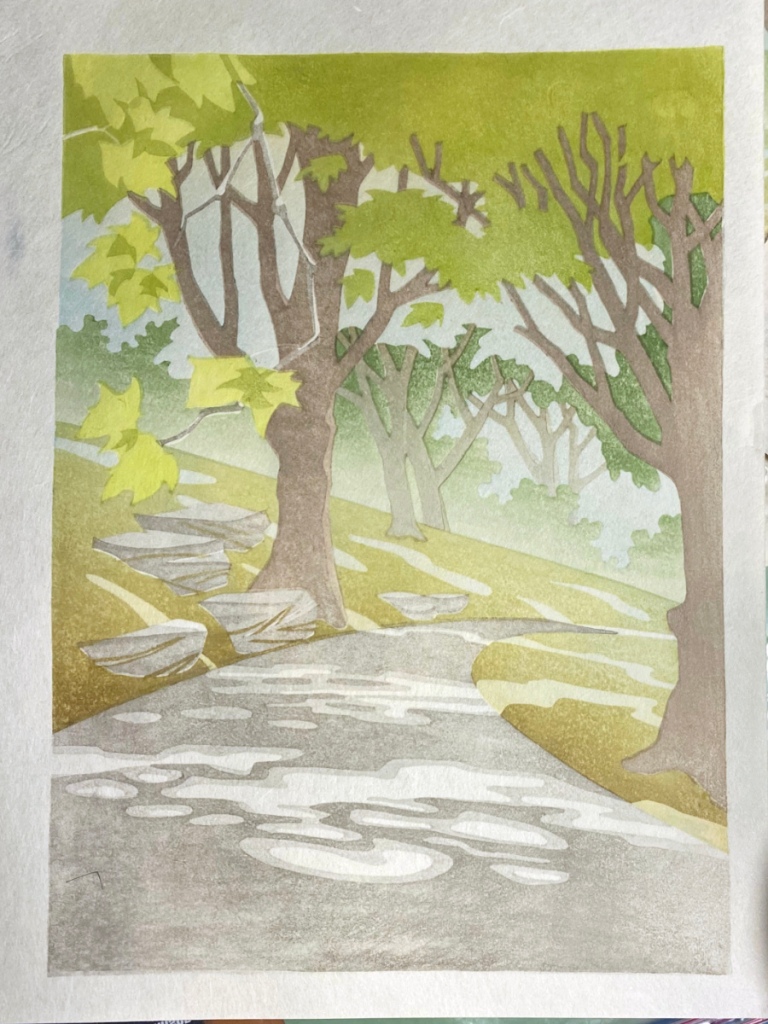

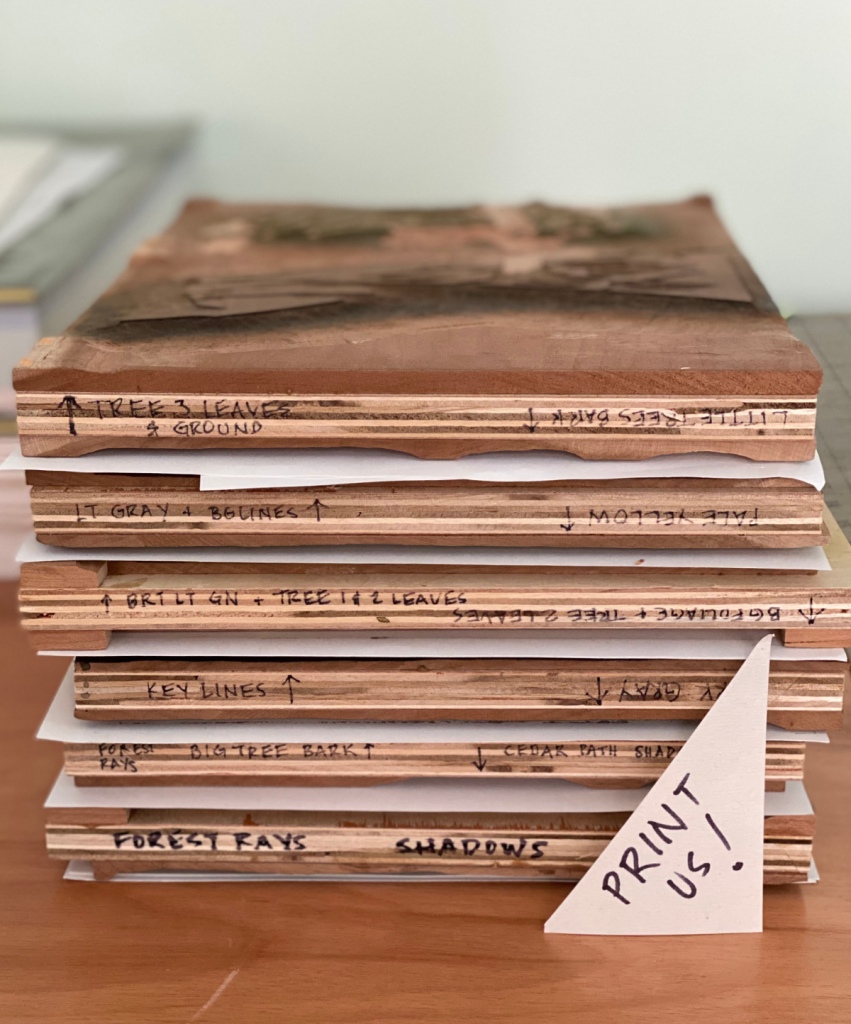

Instead of starting in on the new carving, I printed the first impression of Forest Rays. I can carve later, when I have a few minutes, but printing takes a chunk of time, and today I had the time.

I’m printing on some Shin Hosho I got from Woodlike Matsumura a few years back. It’s pretty tough paper! I’m able to rub it without a sheet of baking parchment to protect it. One drawback is the kind of “chiri” in the paper. All handmade kozo paper has bits of junk – bark, dirt, etc. – included in it. This one has tiny rocks! I picked out 4 little rocks (OK, they are sand grains, but large ones) in these 23 pieces of washi before starting the print run. This is important so as not to damage the blocks or the baren. Other than that, I like this paper a lot. It is tough and dimensionally stable. It needs a lot of pressure for a smooth impression, but using that, it is possible to print quite smoothly.

So, I’ve officially started printing Forest Rays! No telling how long it will take; the test print has 27 or so impressions so far and that is not all of them. Also, JLPT (Japanese Language Proficiency Test) is next week and I really need to study!