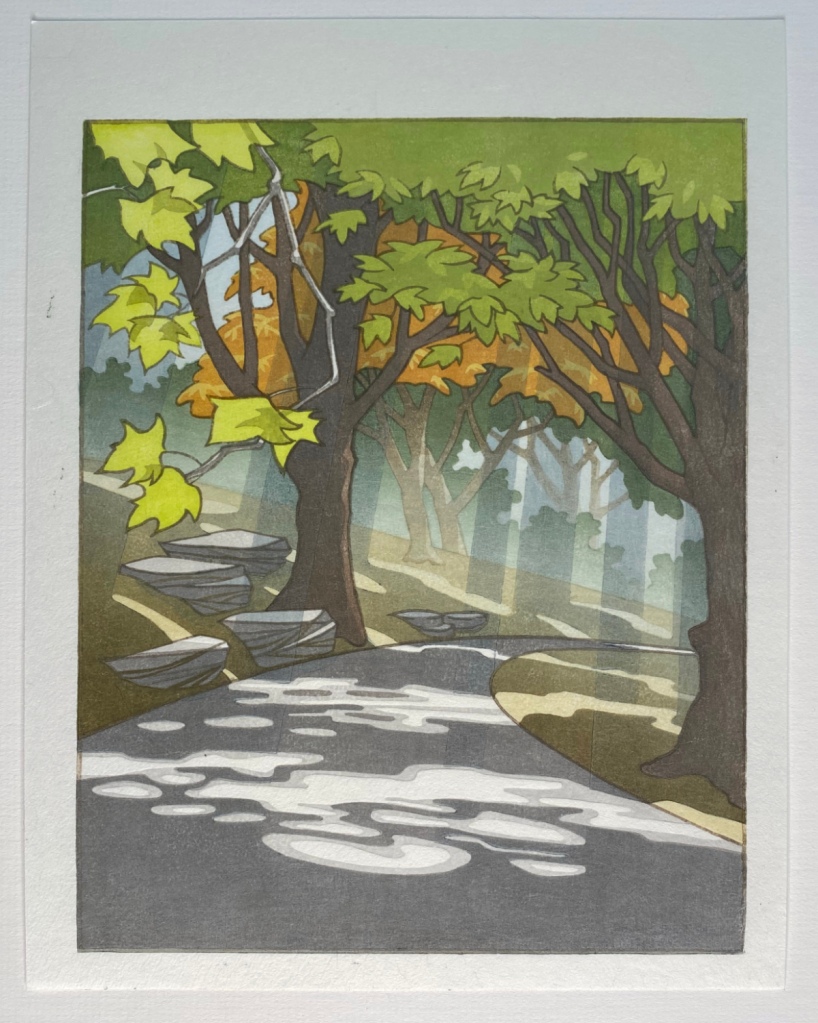

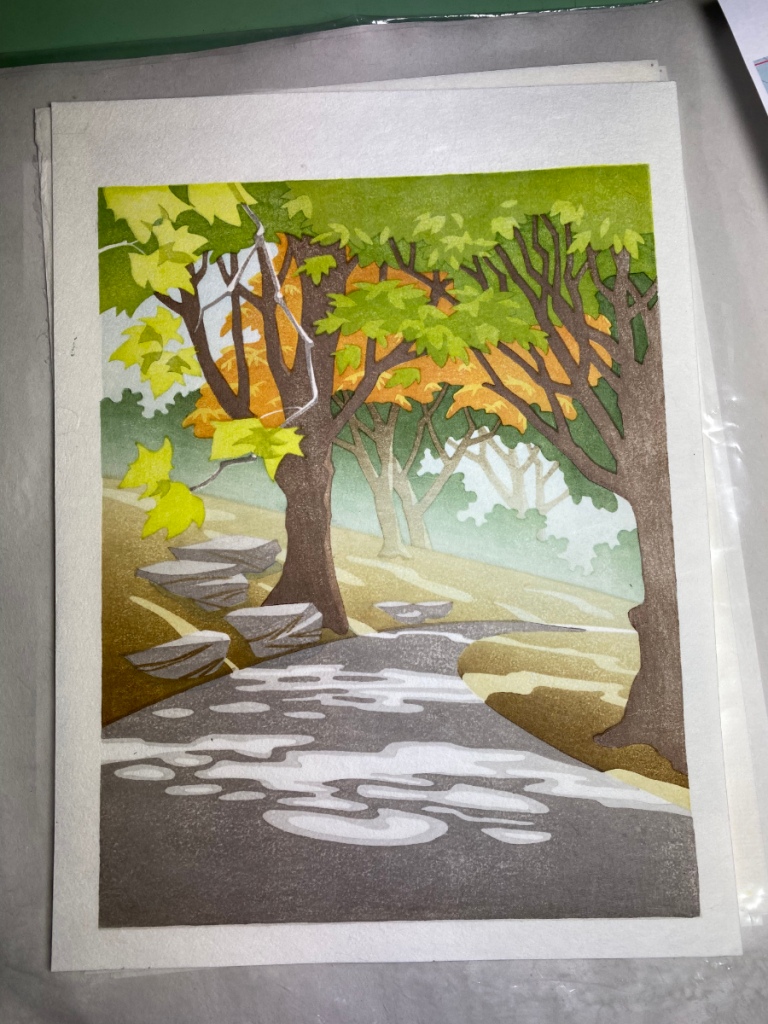

What did I do in 2022? I finally finished Forest Rays! At least I think I am done. The prints are still in the drying boards and will need a careful look-over before I add them to the store, but here’s a preview. I think I captured the feeling I was looking for – humid forest, light streaming through the branches, leaves caught in sunlight glowing brightly.

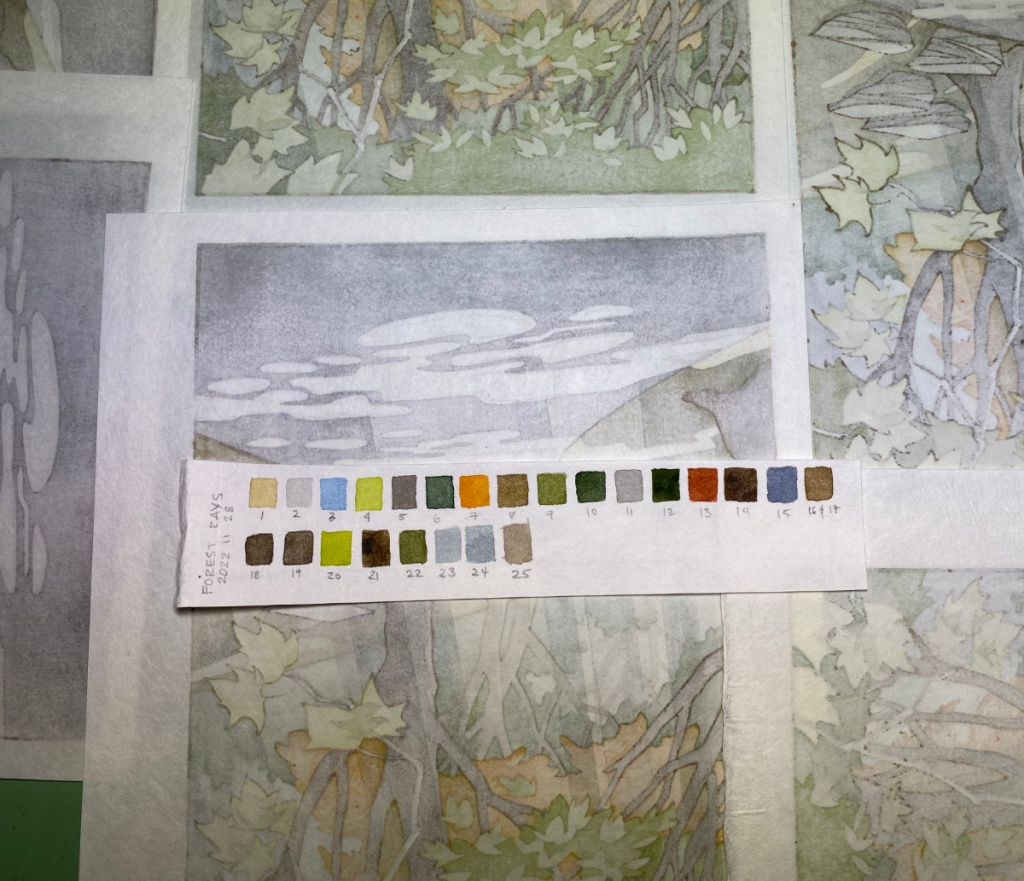

7 pieces of wood (6 self-made cherry ply and 1 shina ply from McClain’s), 19 printable areas including the key block, 25 impressions. (I had prepared separate key lines for the trees and foliage in the distance, but decided not to use them – that would have made 26 impressions!)

The paper is Shin Hosho from Woodlike Matsumura. When I started printing, I thought “Excellent, this paper is really tough, and I’ll need it for this print!” but by the end it was quite soft and barely hanging on. I had thrown in a few sheets of Student Kozo as warm-up sheets, but I gave up on them about 18 impressions in because they were fouling the blocks with fibers that kept coming off.

I’m looking forward to the next print! It will be a simple one, and I’ll aim to finish within a month – fingers crossed. Back to the carving bench!